Meet Super Orange: The Heavy-Duty Cleaner Built for Tough Jobs

In the world of industrial coatings, cleaning and surface preparation are everything. Whether you’re restoring aging membrane systems, coating warehouse floors, or tackling oil-stained concrete, a clean surface is the foundation for long-lasting performance. That’s why Oak Ridge Foam & Coating Systems, Inc. is thrilled to introduce Super Orange Cleaner, our powerful new cleaning solution…

The Best Graco Spray Guns: A Pro’s Guide

Choosing the right spray gun can make the difference between a smooth spray foam or coating job and costly downtime. Graco has earned a reputation for high-quality, reliable spray guns, which is why we’re a proud Graco equipment distributor. With several Graco spray guns to choose from, deciding which is the best one for your…

Quick Guide to Surface Preparation for Polyurea Coating

Polyurea’s rapid cure time and high performance mean there’s little margin for error. Without proper substrate preparation, you may end up with issues like delamination, blistering, and poor adhesion, resulting in expensive rework or failed applications. Proper polyurea substrate preparation is key to a successful, long-lasting coating, minimal waste, and customer satisfaction. Careful attention to…

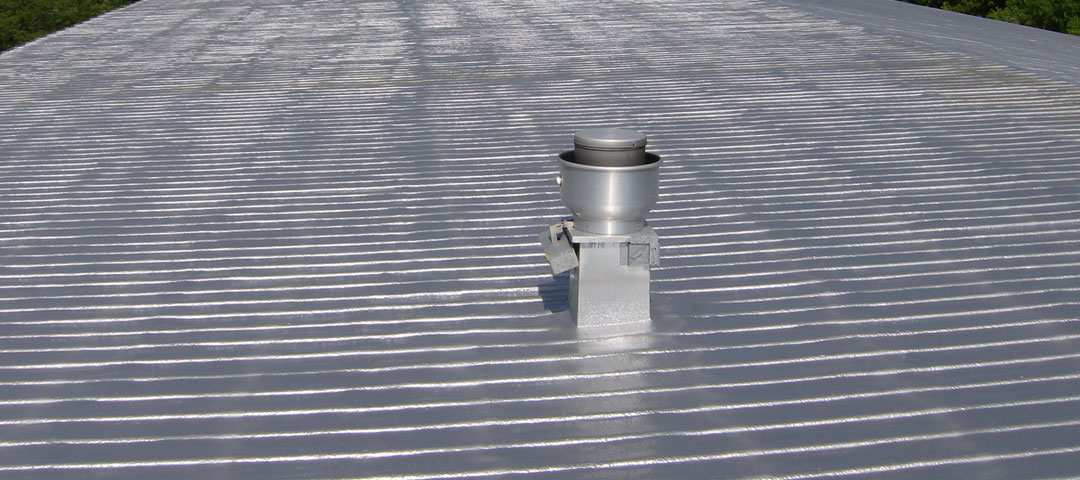

Boost Your Margins with Fast-Turnaround Polyurea Roof Coating Projects

In today’s competitive contracting market, speed and efficiency are everything—especially when it comes to roofing. Every hour you shave off a job translates into more revenue and less overhead. That’s where polyurea roof coatings come in. These high-performance coatings offer a game-changing advantage for contractors and roofers looking to maximize profits without compromising quality. Fast…

Polyurea vs. Silicone vs. Acrylic: Which Roof Coating Wins?

As a roofing contractor, choosing the right roof coating system is essential for client satisfaction and a successful business. Whether you’re restoring an aging flat roof or protecting a new surface, the right coating can extend the roof’s life, improve energy efficiency, and reduce maintenance costs. Polyurea, silicone, and acrylic roof coatings are three of…

How Much Does It Cost to Start a Spray Foam Insulation Business?

It costs approximately $118,000 to $250,000+ to start a spray foam insulation business. This includes key equipment and materials, marketing, operational costs, and more. These start-up costs can vary depending on the size of your business and key services you offer. Spray foam insulation is a profitable and in-demand service. Understanding the cost breakdown will…

Enhance Agricultural Operations with Polyurea Coatings & Spray Foam Insulation

If you work on a farm or in agricultural operations, you know firsthand how pests, weather, and other environmental factors can impact your productivity, equipment longevity, and overall produce or livestock quality. Challenge: Environmental Factors Impact Agricultural Operations and Productivity Some of the most common challenges for farms across the United States include: Feed bag…

What is the Best Type of Spray Foam Machine?

Have you been using the wrong spray foam machine? In the world of spray foam insulation, three types of machines dominate the market—electric, hydraulic, and air-driven. Each has its strengths, weaknesses, and ideal use cases. Let’s break them down so you can confidently select the machine that best fits your needs. 1. Electric Spray Foam…

Understanding Different Spray Foam Rig Options

When it comes to spray foam and polyurea coating, your spray foam rig is likely the biggest investment you’ll make. Choosing the right rig involves tailoring the entire spray foam trailer setup to fit your workflow, job requirements, and budget. From trailer styles and layouts to the equipment housed inside, every decision matters. Let’s break…

Get Your Spray Foam Business Ready for 2025

Whether you’re an experienced professional or just starting out, now is the perfect time to upgrade equipment, train your team, and refine your approach to ensure success in the new year. Let’s discuss some key strategies to help you get your spray foam business ready for the opportunities and challenges ahead. Organize Equipment and Supplies…